Application

Silicone rubber is resistant to extreme temperature conditions, as for high (up to 180 °C, briefly even to 250 °C), so also for low (-60 °C) temperature. It has a high point (temperature) of inflammability, it is halogen-free, releases no corrosive gases at combustion, and around the conductor is formed additional insulation of silicone-oxide ashes. Due to a higher electrical resistance, tinned copper is also more suitable for higher temperatures (up to 220 °C) than bare copper. Such composition of these conductors makes them applicable in extreme temperature environment, for inst. in steel production, aircraft industry, same as in shipbuilding, cement plants and glass and ceramics factories, in electric power plants etc. They are also suitable for inner wiring of lighting, heating elements, burners, furnaces etc. To retain its mechanical properties at temperatures higher than 90 °C, silicone rubber needs to be properly ventilated or laid outdoor or in tubes. Glass fibers increase mechanical resistance of conductor.

Standards

DIN VDE 0282 part 3

DIN VDE 0250 part 1

HRN HD 22.3 S3

IEC 60245-3

Construction

Conductor: tinned copper conductor, fine wired stranded, class 5 acc. to IEC 60228 / HD 383 / DIN VDE 0295

Insulation: silicone rubber

Braid: glass fiber grid

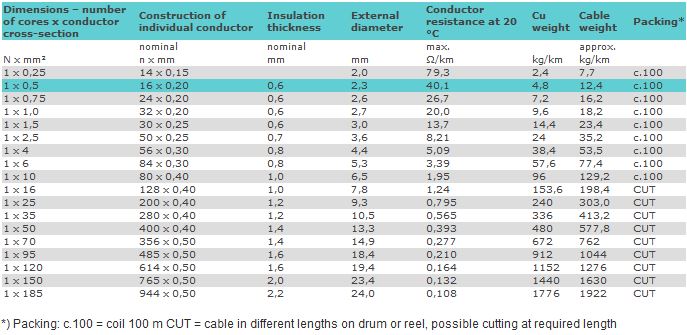

Technical data