Application

Power and signal shipboard cable for fixed installation at all ship’s levels (including outer deck) acc. to IEC 60092-352 standard. Specially suitable for passenger ships because of improved characteristics under fire. Also applied at open sea platforms. Copper braid acts as reinforcement and screen against external electromagnetic impacts.

advantages:

– halogen-free, no release of toxic and corrosive gases under fire

– reduced smoke manifestation under fire

– no flame propagation in vertical cable bundle, flame retardant

– resistant to oils and greases

– improved mechanical characteristics, resistant to scraping and vibrations

– smaller cable diameter and weight

Standards

IEC 60092-350

IEC 60092-353

Construction

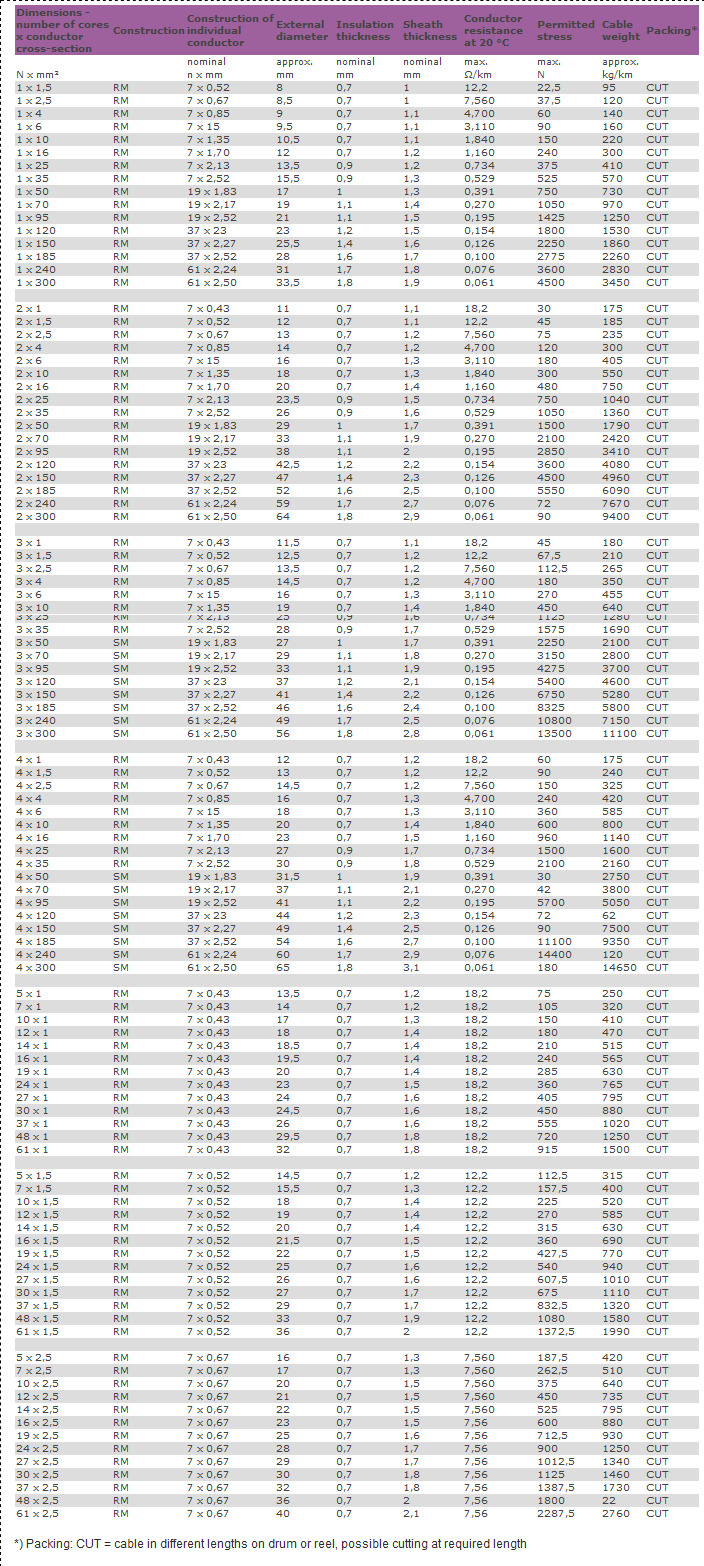

Conductor: bare or tinned copper conductor, multi wire stranded, class 2 acc. to IEC 60228 / HD 383 / DIN VDE 0295, round or sector

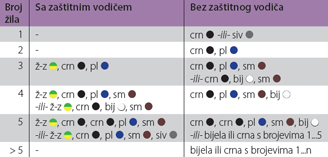

Insulation: cross-linked polyethylene – XLPE, acc. to IEC 60092-351 (more recent mark for cross-linked polyethylene: PE-X), concentrically stranded cores, with or without green-yellow protective conductor

Filler / inner sheath: polyolefin based compound; or without filler, with separator of polyester tape

Armour / Screen: braid of tinned copper wires, min. overlap 90%

Sheath: polyolefin, type SHF1 or SHF2 acc. to IEC 60092-359

sheath colour: black or grey

Technical data

Temperature range:

during installation:-20 °C up to +70 °C

fixed installed: -30 °C up to +80 °C

max operating temperature: 90 °C (or 85 °C)

Nominal voltage: Uο/U = 0,6/1 kV

Test voltage: 3,5 kV

Minimal inner bending radius:

round conductor: 6D

sector conductor: 8D

Flame retardant: IEC 60332-1

Flame resistant: IEC 60332-3 kat. A

Halogen-free: IEC 60754-1

Non-corrosive combustion gases: IEC 60754-2

Low smoke density: IEC 61034-2