Application

NHXH cables suitable for fixed installation in dry and damp environment, on or under plaster, on cable trays, same as in walls and concrete. Not intended for direct laying in ground or water. For outdoor application can be laid in tubes, but in that case should be taken all precautionary measures necessary to prevent water penetration into the tubes. Suitable for electric installations with marked fire-fighting and function preserving requirements, for alarm systems, fire sensors, evacuation elevators and other supply systems in an emergency. Appropriate for application in all situations where people and material goods need to be protected in case of fire. Recommended for public buildings frequented by a lot of people, and for buildings of high material value, for industrial complexes, electric power plants, transformer stations, municipal facilities, hotels, shopping malls, hospitals, schools, airports, underground railways and similar. Important – NHXH cables should not be laid on common trays, but on fire-resistant trays which retain their geometry in case of fire. Keeping NHXH cables in the same position in case of fire, enables additional protection of cable conductivity, by means of the mineral layer discharged around the cable at increased temperature.

advantages:

– halogen-free, no release of toxic or corrosive gases under fire

– reduced smoke occurrence under fire

– no flame propagation in vertical cable bundle

– preserved electric function of the system within set time period

Standards

DIN VDE 0266

FE180: IEC 60331

DIN VDE 0472 part 814

E30: DIN 4102 part 12

Construction

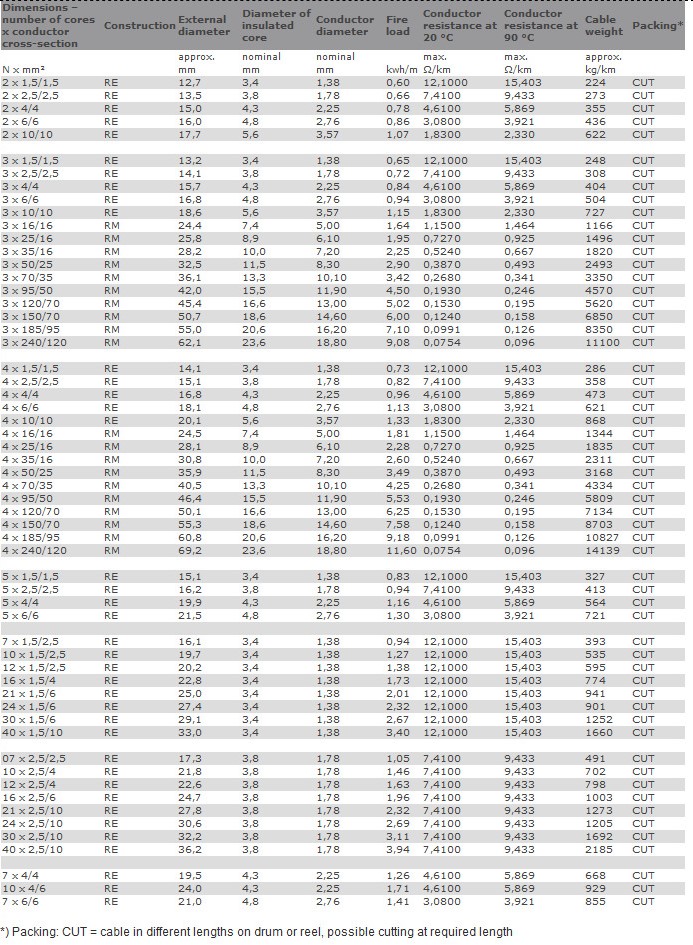

Conductor: Cu, class 1 or 2 acc. to HRN HD 383 / IEC 60228 / DIN VDE 0295

class 1: solid, round (RE)

class 2: multi wire stranded, round (RM) or sector (SM)

Insulation 1: mica tape, fire resistant halogen-free dielectric

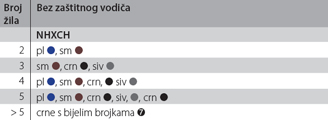

Insulation 2: cross-linked halogen-free polymer, HXI1 acc. to VDE 0266, concentrically stranded cores, colour marked acc. to HRN HD 308 S2 / VDE 0293-308, without yellow-green protective conductor

Filler: filler applied in multi core, extruded halogen-free polymer or lapped glass fibres

Concentric conductor: in inner layer spirally wrapped round copper wires, in external layer copper tape wrapped in counter-helix

Sheath: cross-linked thermoplastic halogen-free flame retardant polyolefin bond HM1 or HM4 acc. to HD 604 S1 and VDE 0276-604

sheath colour: orange

Core colour marking: acc. to HRN HD 308 S2 / VDE 0293-308

Technical data

Temperature range:

during installation: -5 °C up to +50 °C

fixed installed: -15 °C up to +90 °C

max. operating temperature: 90 °C

at short circuit of max. 5 s: up to 250 °C

Nominal voltage: Uο/U = 0,6/1 kV

Test voltage: 4 kV

Max. tensile strength of Cu conductor: 50 N/mm²

Minimal inner bending radius: 12D

Flame retardant: IEC 60332-1

No flame propagation in vertical cable bundle: IEC 60332-3

Halogen-free: IEC 60754-1

Non-corrosive combustion gases: IEC 60754-2

Low smoke density: IEC 61034-2

Insulation integrity under fire, no short circuit FE180 – fire-resistant: IEC 60331

Circuit integrity under fire – E90: acc. to DIN 4102 part 12, 90 minutes