ENPI, Lider në zgjidhjet Energjitike

Partneri juaj i besuar për zgjidhje të avancuara në sektorin e energjisë!

NSHTou

Application

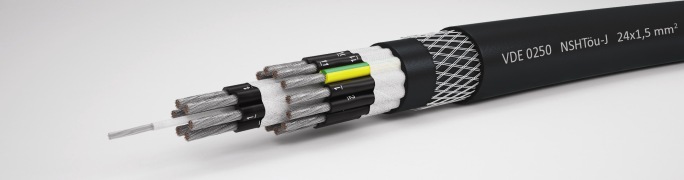

Neoprene insulated robust cable used as supply and signalling cable in hard operating conditions, requiring constant cable shifting under heavy mechanical load, under different weather and chemical conditions. Specially suited for application with frequent winding and unwinding accompanied by traction and torsion loads. Possible inner and outdoor application, cable resistant to oils, moisture, water, UV-irradiation, cold, ozone, solvents, greases, acids, alkali, gasoline etc. Used for machinery in construction, mining, industry and railways, at transport, in jacks and cranes.

Standards

DIN VDE 0250 part 814

Construction

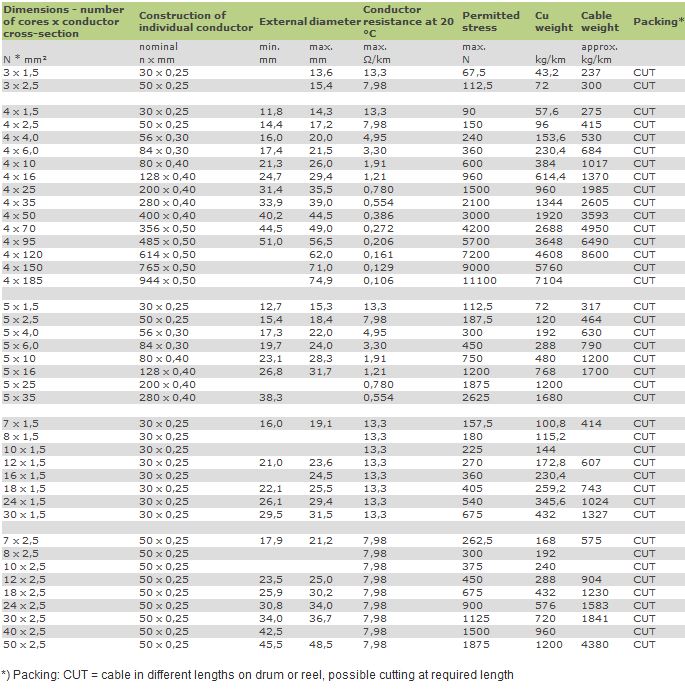

Conductor: tinned copper conductor, fine wired stranded, class 5 acc. to IEC 60228 / HD 383 / DIN VDE 0295

Insulation: rubber compound on ethylene-propylene basis (EPM, earlier: EPR), i.e. 3GI3 or GI1 acc. to DIN VDE 0207 part 20, concentrically stranded cores in layers

Inner sheath: rubber compound on poly-chloroprene basis (CR), i.e. 5GM3 acc. to DIN VDE 0207 part 21

Textile braid: fitted in inner or external sheath to prevent cable torsion

Sheath: rubber compound on poly-chloroprene basis (CR) (= Neoprene), i.e. 5GM2 or 5GM3 acc. to DIN VDE 0207 part 21

sheath colour: black

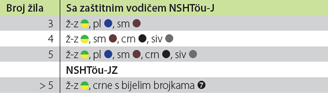

Core colour marking: acc. to HD 308 S2 / VDE 0293-308

Technical data

Temperature range:

during application:

-25 °C up to +60 °C

fixed installed:

-40 °C up to +80 °C

at short circuit of max. 5 s:

up to 200 °C

Nominal voltage: Uο/U = 0,6/1 kV

Test voltage: 2500 V

Max. permitted voltage:

in AC installations: Uο/U = 0,7/1,2 kV

in DC installations: Uο/U = 0,9/1,8 kV

Specific el. resistance of insulation: min. 10 MΩ x km

Max. tensile strength:

static: 15 N/mm²

dynamic: 30 N/mm²

Conveyor speed: up to 120 m/min

Other characteristics: resistance to oil, UV-irradiation, greases, gasoline, weather conditions

Behaviour in fire: IEC 60332-1