ENPI, Lider në zgjidhjet Energjitike

Partneri juaj i besuar për zgjidhje të avancuara në sektorin e energjisë!

NSSHou

Application

Cable for connection of electrical devices, machines and tools in conditions of heavy mechanical loads, in dry and damp inner and external areas and extreme conditions, for inst. mines (free of methane), construction sites, quarries, industry. Also suitable for fixed installation on wall surface. Long lifetime due to resistance to heat, water, ozone, impacts, crushing, friction, oils and greases.

Standards

DIN VDE 0250 part 812

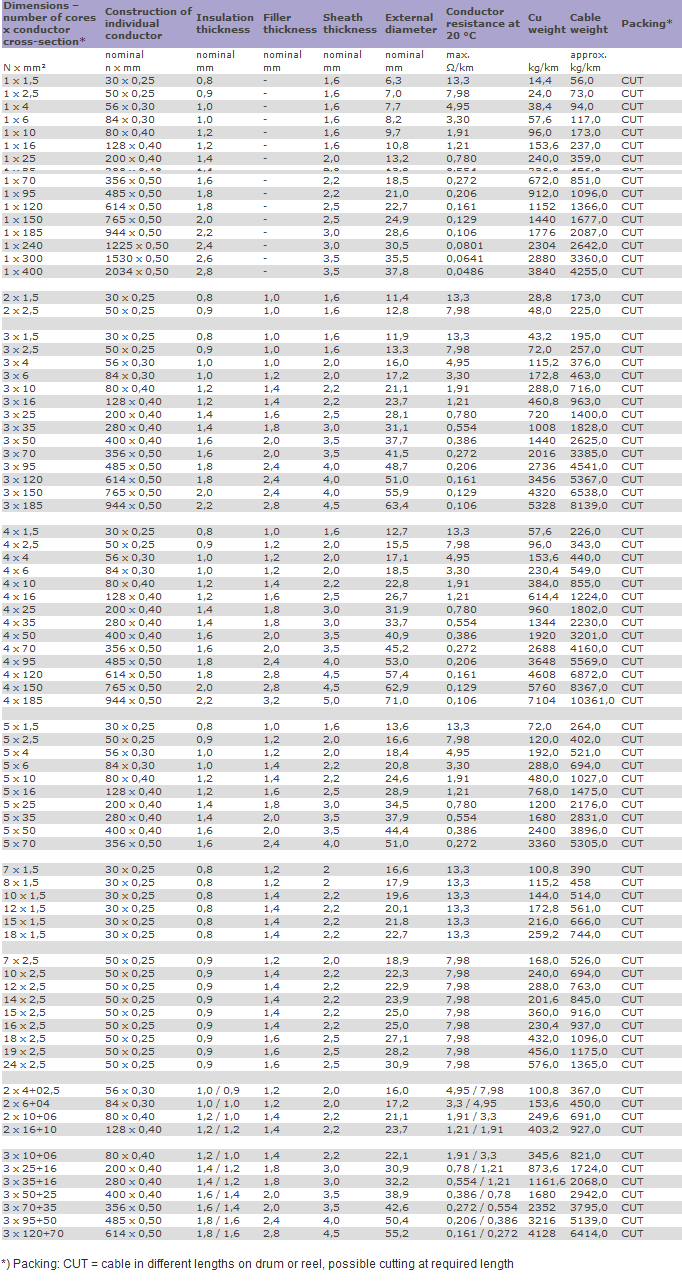

Construction

Conductor: tinned copper conductor, fine wired stranded, class 5 acc. to IEC 60228 / HD 383 / DIN VDE 0295

Insulation: rubber compound on ethylene-propylene basis (EPM, earlier: EPR), i.e. 3GI3 acc. to DIN VDE 0207 part 20, cores stranded in layers

Filler: rubber compound GM1b acc. to DIN VDE 0207 part 21

Sheath: rubber compound on poly-chloroprene basis (CR), i.e. 5GM5 acc. to DIN VDE 0207 part 21

sheath colour: yellow

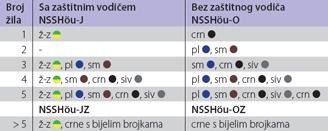

Core colour marking: acc. to HRN HD 308 S2 / VDE 0293-308

Technical data

Temperature range:

fixed installed: -40 °C up to +80 °C

at usage with bending: -25 °C up to +80 °C

maximal operating temp.: +90 °C

at short circuit of max. 5 s: up to 200 °C

Nominal voltage: Uο/U = 0,6/1 kV

Test voltage: 3 kV

Maximal operating voltage:

alternating current three-phase and single-phase: Uο/U = 720/1200 V

direct current: Uο/U = 900/1800 V

Maximal tensile strength: 15 N/mm²

Specific el. resistance of insulation: min. 20 MΩ x km

Minimal inner bending radius:

for fixed installation: 4D

usage with bending: 10D

Behaviour in fire: IEC 60332-1

Oil resistance: acc. to DIN VDE 0472 part 803, method A

Properties: nsulation resistant to oil, greases and chemicals, ozone